Medical microneedles are tiny needle-like devices that are widely used in medical cosmetology and some medical fields, so they are also called cosmetic microneedles, puncture needles, etc. They have the advantages of minimally invasive, precise, safe and efficient.

Due to the wide application and particularity of medical microneedles, the electroplating layer of medical microneedles plays an important role in their application. The following introduces the common electroplating layers of medical microneedle electroplating processing.

Chrome plating

Hard chrome plating is a common electroplating material with high hardness, wear resistance and good corrosion resistance. It can improve the surface hardness and wear resistance of medical microneedles and extend their service life. However, chromium is a heavy metal that may pose potential risks to human health. Therefore, when using medical microneedles plated with hard chrome, it is necessary to ensure that they comply with relevant safety standards and regulations.

Titanium plating

Titanium is a metal with good biocompatibility. Titanium plating can improve the biocompatibility of medical microneedles and reduce irritation and adverse reactions to the human body. Titanium also has high strength and corrosion resistance and can withstand certain pressure and chemical erosion.

Silver plating

The silver plating layer has good conductivity and antibacterial properties. In medical applications, silver-plated medical microneedles can be used for electrical stimulation therapy or as biosensors, while also reducing bacterial growth and the risk of infection. However, the silver layer is easily oxidized in the air, and appropriate protective measures need to be taken to maintain its performance.

Gold plating

The gold-plated layer has excellent conductivity, chemical stability and biocompatibility. It can be used to make high-precision medical microneedles, such as those used for nerve stimulation or cell culture. The cost of the gold-plated layer is high, but its performance is stable and its service life is long.

Since its establishment, HYP has focused on the barrel plating of precision electronic parts of copper-based and iron-based materials, so it has a good technical foundation and sufficient conditions for the surface treatment of precision probes. A long period of research has been conducted on microneedles, and the necessary tanks and fixtures are equipped to prevent the microneedles from being damaged and lost during the electroplating process, while also ensuring the excellent bonding strength and good uniformity of the product's coating.

Related news

-

Common items and methods for precision metal plating testing

Electroplatingisacommonmetalsurfacetreatmentsolution.Electroplatingcannotonlyincreasetheappearanceoftheproduct,butalsoimprovethepe... -

Key points of electroplating of pogo pin parts in precision electronic connector electroplating

Pogopin is a common electronic connector. Due to its size and precision, it is generally processed by roll plating. The following is the key points of electroplating from the three parts of pogopin: spring, barrel and plunger: -

Plating Principles and Classification

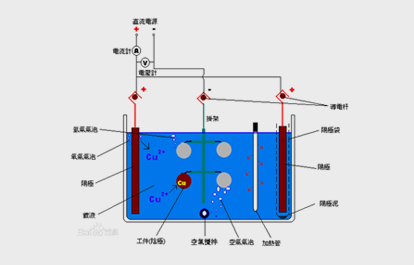

Electroplating is the process of plating a thin layer of other metals or alloys on the surface of certain metals using the principle of electrolysis. It is a process of using electrolysis to attach a layer of metal film to the surface of metal or other material parts to prevent metal oxidation ( Such as rust), improve wear resistance, conductivity, reflectivity, corrosion resistance and... -

Environmental nickel free plating manufacturer - copper tin zinc plating

One in every 1 million people in the world is allergic to metals. The most common allergen metal is nickel. Once allergies occur, it can cause contact dermatitis manifestations such as redness, itching, and yellow water around the contact. These are all adverse reactions caused by the release of metal ions. Once metal allergic dermatitis occurs, the most fundamental and effective treatment The solution is to isolate the allergen. -

Wastewater Treatment at HYP

Electroplating enterprises and surface treatment enterprises have chemical oxidation, anodic oxidation, galvanizing, zinc-nickel alloy plating, chrome plating, copper plating, gold plating, nickel plating, silver plating and other plating types, and the wastewater produced is very messy.